High-output thermoforming machine for plastic lids, trays, and packaging boxes. Supports PP, PET, HIPS, and PVC sheets up to 550mm wide. Features 530×260mm forming area, 15–28 cycles/min speed, and 24kW total power. Ideal for food, cosmetic, and medical packaging. Fully automatic operation with custom mold support.

N º de Modelo :

YK-TF550Anombre del producto :

Plastic cup lid forming machineVoltaje :

380V 3P 50HZCapacidad de producción :

15-28 cycle/minUso :

to produce plastic lids,medicine/food/daily/electronics/hardwarePuerto de embarque :

Shanghai/ningbo portTiempo de espera :

35daysPeso :

3200kg

The YK-TF550A is a high-performance plastic thermoforming machine designed for producing a wide variety of packaging products such as plastic lids, food trays, cosmetic boxes, hardware blisters, and medical trays.

It supports materials including PP, PET, HIPS, PVC, and GPPS, and offers full-cycle automatic operation: feeding, heating, forming, cutting, and stacking.

Built with a robust 24kW drive and a forming area of 530×260mm, it’s ideal for high-speed, continuous production of precision thermoformed items.

|

Max Sheet Width: 550mm

Maximum Forming Area: 530mm × 260mm

Maximum Forming Depth: 50mm

Speed: 15–28 cycles/min (adjustable)

This generous forming range allows multi-cavity molds, helping manufacturers boost per-cycle productivity and reduce unit cost.

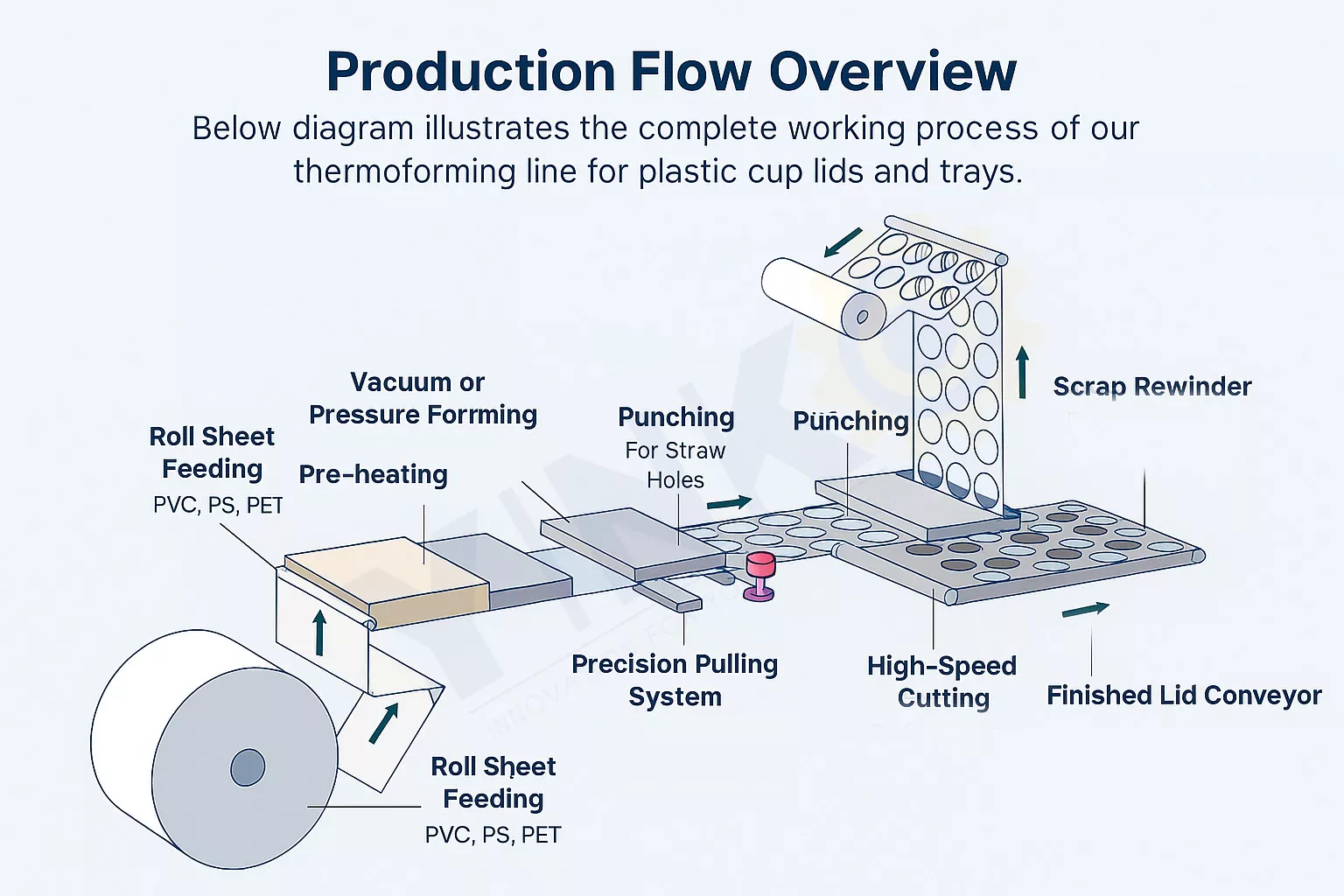

This automatic thermoforming line combines

Roll sheet unwinding & feeding

Electric heating + vacuum/pressure forming

Hole punching, edge cutting & trimming

Stacking and counting of finished lids/trays

Powered by a reliable PLC + touchscreen system, it ensures high precision and minimal scrap rate under 24/7 production.

|

Total Power: 24kW

Compressed Air: 0.6–1.0 MPa

Air Consumption: > 3 m³/min

Water Cooling: Tap/recycle water, 60L/h

Machine Weight: 3200 kg

Packing Size: 4600×1500×1900 mm

Fully automatic: feeding → heating → forming → punching → cutting → stacking

Suitable for both transparent and colored sheet rolls

Servo-controlled pulling system for high positioning accuracy

CE-compliant safety cover and emergency stop mechanism

Easy mold change system, supports custom mold development

Scrap rewinder, automatic stacking & counting system

|

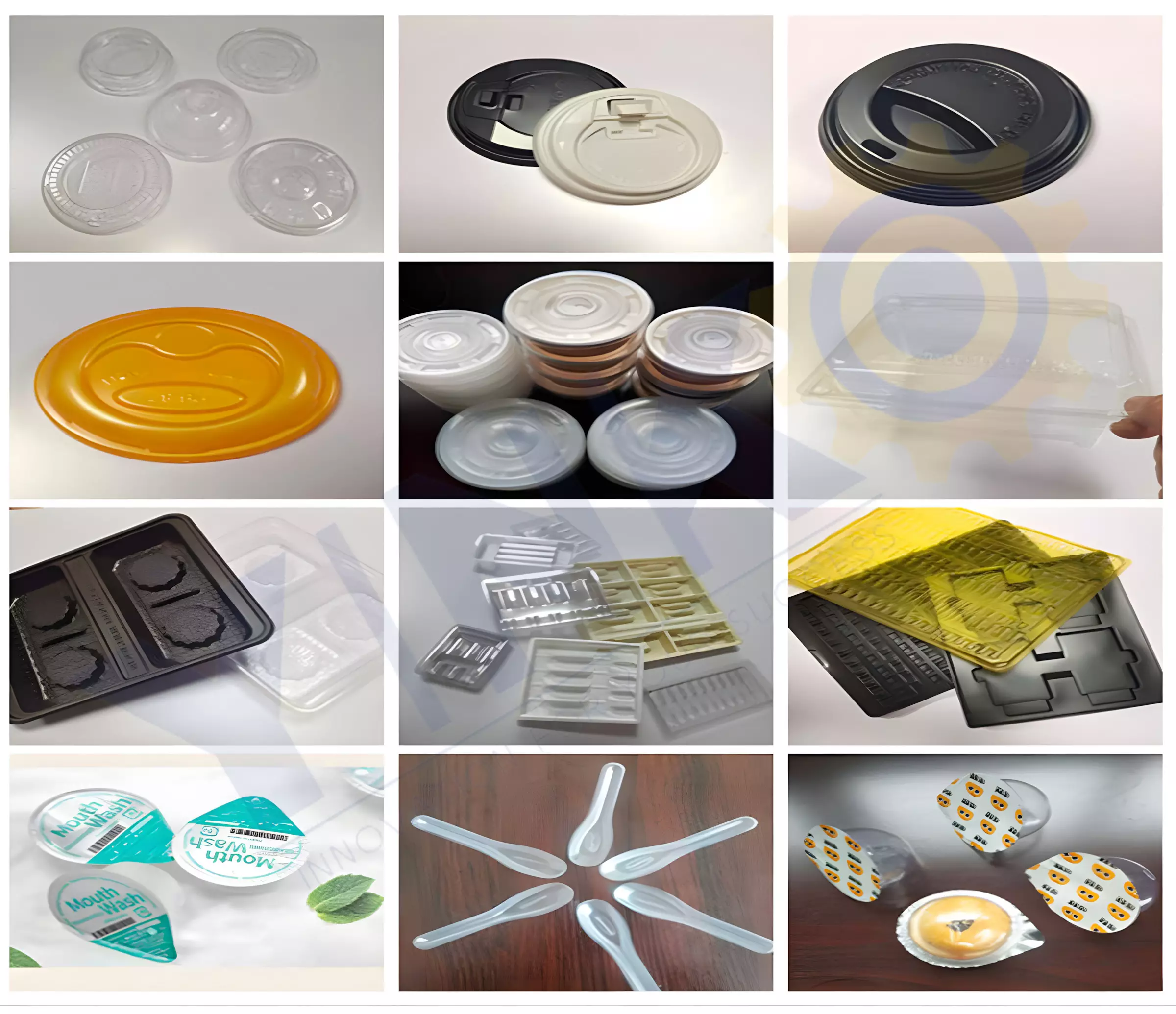

Drink cup lids (flat/dome)

Disposable food trays, lunch boxes

Cosmetic and skincare packaging

Medical trays, pill pack shells

Hardware & tool blisters

Custom OEM thermoformed parts

|

Disposable packaging manufacturing

Food & beverage packaging supply

Cosmetics and medical packaging

Retail blister product producers

OEM and ODM packaging line integrators

Q: Can this machine handle PLA or biodegradable sheets?

A: It supports PET, HIPS, GPPS, PVC, and partially PLA sheets with proper heating settings.

Q: How many cavities can fit into the forming area?

A: That depends on the lid or tray size—e.g., for 90mm cup lids, typically 4–6 cavities are possible in 530×260mm area.

Q: Does this machine support auto stacking?

A: Yes, it can be equipped with a stacking and counting unit, or integrated into a full packaging line.

Q: What type of molds are supported?

A: We provide custom aluminum molds with or without logo embossing, designed based on your sample or CAD drawing.