La guía definitiva para máquinas de vasos de papel: encuentre la máquina adecuada para sus necesidades

La guía definitiva para máquinas de vasos de papel: encuentre la máquina adecuada para sus necesidades

May 12, 2024

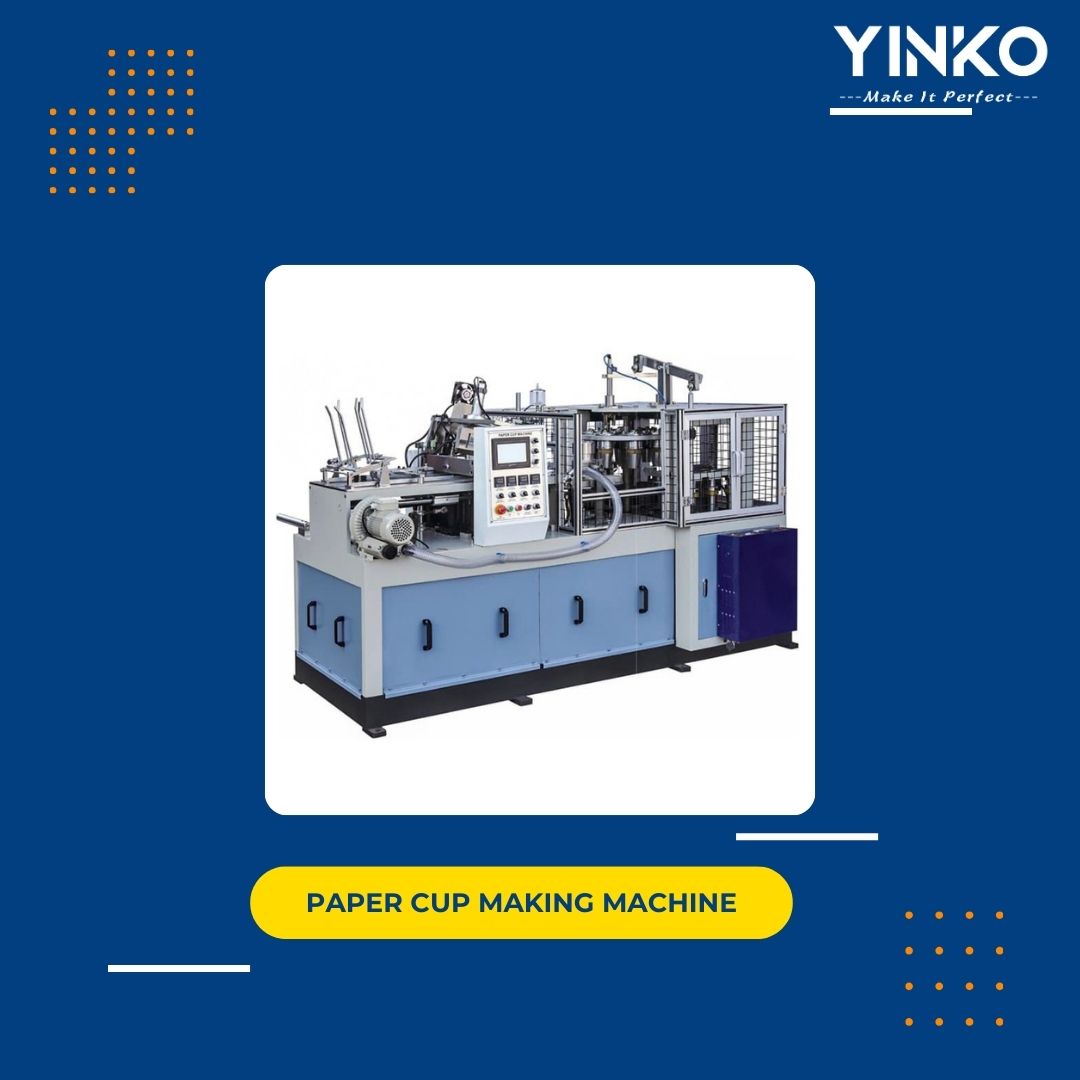

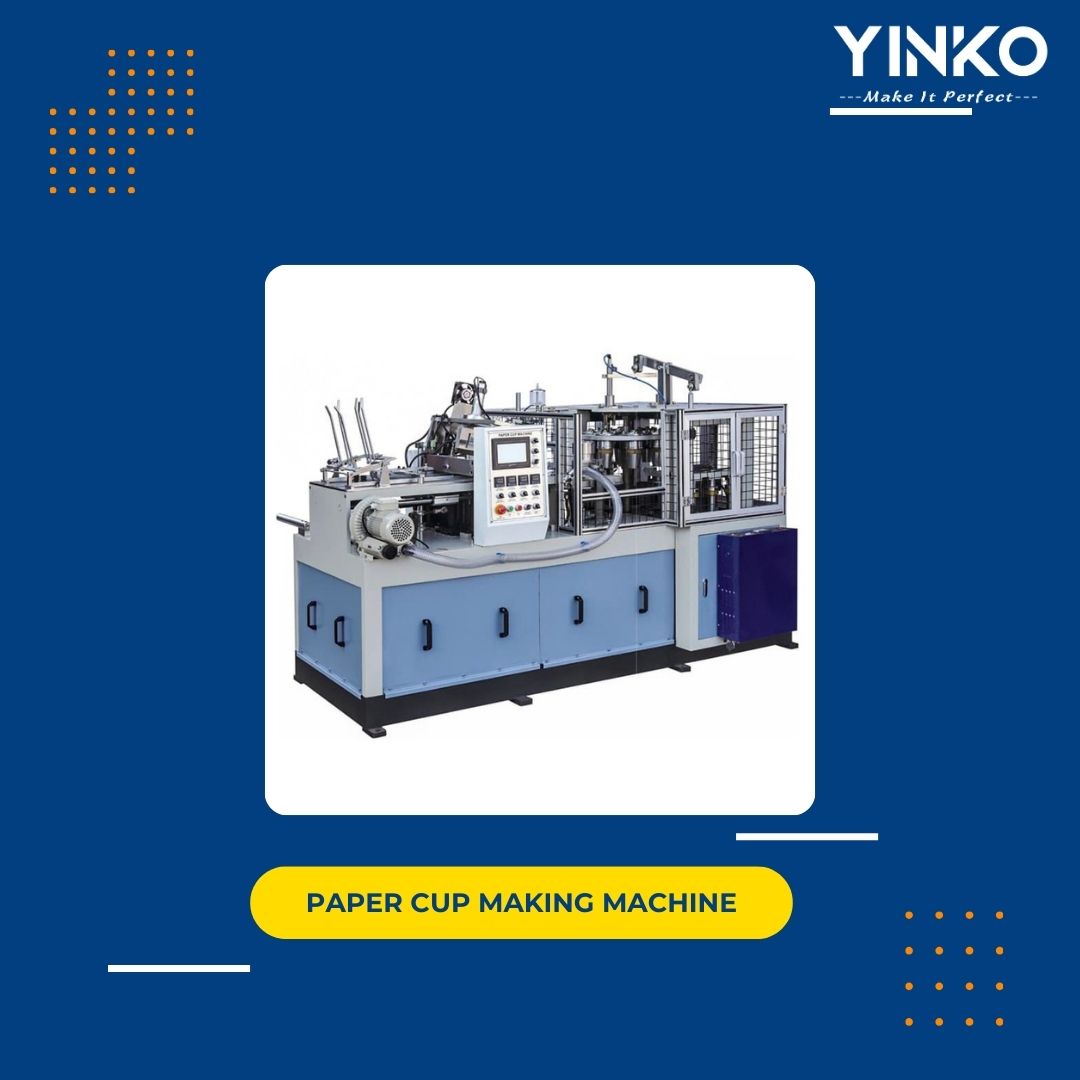

Los vasos de papel son una parte integral de nuestra vida diaria, especialmente en la industria de alimentos y bebidas. Desde cafeterías y cadenas de comida rápida hasta hospitales y lugares para eventos, la demanda de vasos desechables se está disparando. Con un énfasis cada vez mayor en la sostenibilidad, los vasos de papel se han convertido en una alternativa más ecológica al plástico. Este cambio, a su vez, ha estimulado la necesidad de máquinas de vasos de papel eficientes capaces de satisfacer altas demandas de producción y al mismo tiempo cumplir con los estándares ambientales. Esta guía tiene como objetivo brindar una descripción general completa de las máquinas de vasos de papel, ayudándolo a comprender sus especificaciones técnicas, aplicaciones y tendencias futuras, para que pueda tomar una decisión informada al invertir en la máquina adecuada para sus necesidades.Especificaciones técnicas de Máquinas de vasos de papel1.1 Comprensión de la capacidad de la máquinaAl seleccionar una máquina para fabricar vasos de papel, una de las primeras cosas a considerar es su capacidad. Esto se refiere a la capacidad de la máquina para producir una cantidad específica de tazas por minuto (CPM). Las máquinas de alta velocidad pueden producir entre 60 y 100 tazas por minuto, lo que las hace ideales para operaciones a gran escala. Sin embargo, si tiene una empresa más pequeña o recién está comenzando, una máquina con un CPM más bajo puede ser suficiente. Otro factor importante es el rango de tamaño de copa. Algunas máquinas están diseñadas para manejar una amplia gama de tamaños, desde pequeñas tazas de café expreso hasta grandes tazas de refresco, mientras que otras son más especializadas. Comprender sus necesidades de producción específicas le ayudará a determinar la capacidad adecuada para su negocio. Además, es importante considerar el consumo de energía. Las máquinas con tasas de producción más altas suelen consumir más energía, por lo que equilibrar la eficiencia de la producción con los costos de energía es crucial para la rentabilidad a largo plazo. 1.2 Compatibilidad de materiales El tipo de papel y revestimientos utilizados en la producción de vasos de papel pueden afectar significativamente el rendimiento de la máquina. La mayoría de las máquinas para fabricar vasos de papel están diseñadas para trabajar con espesores de papel específicos, que normalmente oscilan entre 150 y 400 gramos por metro cuadrado (GSM). El grosor del papel influye en las propiedades de rigidez y aislamiento de los vasos, que son consideraciones importantes según el uso previsto. Los revestimientos son otro aspecto crítico, siendo el polietileno (PE) el más común para la impermeabilización y la resistencia al calor. Sin embargo, debido a las crecientes preocupaciones medioambientales, hay un cambio hacia recubrimientos biodegradables como el ácido poliláctico (PLA). Es fundamental elegir una máquina que sea compatible con los tipos de materiales que planea utilizar. Además, si necesita vasos impresos, considere los tipos de tintas con las que puede trabajar la máquina. Las tintas a base de agua son una opción ecológica popular, pero debes asegurarte de que tu máquina pueda manejarlas sin comprometer la calidad de impresión. 1.3 Dimensiones y peso de la máquinaLas dimensiones físicas y el peso de una máquina de vasos de papel son consideraciones importantes, especialmente cuando el espacio es limitado. La mayoría de las máquinas industriales para vasos de papel son relativamente grandes y requieren un espacio considerable. Es importante asegurarse de que el espacio de la máquina se ajuste cómodamente a su área de producción, con suficiente espacio para que los operadores trabajen de forma segura y eficiente. El peso es otro factor, especialmente en instalaciones donde es necesario mover la máquina con frecuencia. Las máquinas más pesadas ofrecen más estabilidad, pero pueden resultar difíciles de transportar o reposicionar. Si la portabilidad es una prioridad, considere máquinas diseñadas para facilitar el movimiento, aunque esto podría ocurrir a expensas de la capacidad o la velocidad de producción. Al planificar su instalación, tenga en cuenta espacio adicional para materiales, acceso de mantenimiento y almacenamiento. 1.4 Nivel de automatizaciónEl nivel de automatización en las máquinas de vasos de papel varía ampliamente, desde modelos manuales que requieren la intervención constante del operador hasta sistemas totalmente automatizados que pueden funcionar con una supervisión mínima. Las máquinas manuales son generalmente más asequibles y adecuadas para operaciones a pequeña escala o empresas con presupuestos ajustados. Sin embargo, requieren más mano de obra y su producción puede ser menos consistente. Por otro lado, las máquinas totalmente automatizadas, aunque más caras, ofrecen importantes ventajas en términos de velocidad, coherencia y ahorro de mano de obra. Por lo general, vienen con sistemas de control avanzados que permiten un fácil seguimiento y ajuste de los parámetros de producción. Las máquinas semiautomáticas ofrecen un compromiso: proporcionan cierto nivel de automatización y al mismo tiempo requieren supervisión humana. Comprender el nivel de automatización que mejor se adapta a sus necesidades de producción es esencial para maximizar la eficiencia y el retorno de la inversión. 1.5 Requisitos de mantenimientoEl mantenimiento regular es crucial para que las máquinas de vasos de papel funcionen sin problemas y evitar costosos tiempos de inactividad. Cada máquina viene con su propio conjunto de requisitos de mantenimiento, que van desde tareas de limpieza diarias hasta el reemplazo periódico de piezas de desgaste. Las tareas de mantenimiento de rutina suelen incluir la limpieza del sistema de alimentación de papel, la lubricación de las piezas móviles y la inspección del desgaste. La disponibilidad de repuestos es otra consideración importante; Las máquinas de fabricantes conocidos suelen tener mejores redes de soporte, lo que facilita la obtención de piezas de repuesto. Los costos de mantenimiento pueden acumularse con el tiempo, por lo que es importante tenerlos en cuenta en sus gastos operativos generales. Algunos fabricantes ofrecen contratos de mantenimiento, que pueden brindar tranquilidad y potencialmente reducir los costos a largo plazo al garantizar un mantenimiento profesional regular. Aplicaciones de las máquinas de vasos de papel2.1 Industria de alimentos y bebidasLa industria de alimentos y bebidas es el principal mercado para las máquinas de vasos de papel. Los restaurantes, cafeterías y cafeterías dependen en gran medida de vasos desechables para servir bebidas como café, té y refrescos. Los vasos de papel ofrecen una forma cómoda e higiénica de servir bebidas mientras viaja y, con la creciente tendencia de las marcas personalizadas, muchas empresas optan por máquinas que pueden producir vasos con estampados y logotipos personalizados. Para el catering de eventos, la capacidad de producir grandes cantidades de tazas en poco tiempo es fundamental. Eventos como festivales, conciertos y conferencias requieren una gran cantidad de vasos desechables, lo que hace que las máquinas de vasos de papel de alta capacidad sean indispensables. Además, la integración de vasos de papel con máquinas expendedoras ha provocado un aumento en la demanda de máquinas especializadas que puedan producir vasos adecuados para bebidas calientes, garantizando que mantengan su estructura y no goteen ni se degraden cuando se llenan con líquidos calientes. 2.2 Atención sanitaria y hospitalesEn entornos sanitarios, los vasos de papel se utilizan mucho debido a su naturaleza desechable, lo que ayuda a mantener la higiene y prevenir la contaminación cruzada. Los hospitales y clínicas suelen utilizar vasos de papel para dispensar medicamentos, servir agua a los pacientes y en los laboratorios para la recogida de muestras. La demanda de vasos estériles y de alta calidad ha llevado al desarrollo de máquinas que pueden producir vasos que cumplan con los estrictos estándares requeridos en entornos médicos. Estos vasos especiales a menudo deben producirse en entornos controlados para garantizar que estén libres de contaminantes. Como tal, las máquinas utilizadas en entornos sanitarios suelen estar diseñadas con características adicionales para garantizar el cumplimiento de las normas sanitarias, como sistemas de limpieza automatizados y el uso de materiales estériles. 2.3 Distribución minorista y mayoristaEl sector minorista también desempeña un papel importante en la demanda de máquinas para fabricar vasos de papel. Muchas marcas minoristas, particularmente aquellas del sector de alimentos y bebidas, optan por etiquetas privadas para diferenciar sus productos. Esto ha llevado a un aumento en la demanda de máquinas de vasos de papel capaces de producir vasos de marca personalizada a granel. Los distribuidores mayoristas también dependen de máquinas de alta capacidad para satisfacer las demandas de pedidos grandes. Para las empresas involucradas en el comercio minorista y la distribución, la capacidad de producir una variedad de tamaños y diseños de tazas es crucial, ya que les permite atender a diferentes segmentos del mercado. Además, el auge del comercio electrónico ha abierto nuevas oportunidades para que las marcas minoristas ofrezcan productos personalizados, impulsando aún más la necesidad de máquinas de vasos de papel versátiles. 2.4 Aplicaciones ambientalesA medida que el mundo se vuelve más consciente de los problemas ambientales, ha aumentado la demanda de vasos de papel ecológicos. Las máquinas de vasos de papel que producen vasos biodegradables o compostables están ahora a la vanguardia de la industria. Estas máquinas están diseñadas para trabajar con materiales respetuosos con el medio ambiente, como los recubrimientos de PLA, que se derivan de recursos renovables como el almidón de maíz y son totalmente compostables. Además de producir vasos, algunas máquinas están integradas con programas de reciclaje, lo que permite a las empresas reciclar vasos usados y reducir el desperdicio. Esto no sólo ayuda a las empresas a alcanzar sus objetivos de sostenibilidad, sino que también atrae a consumidores conscientes del medio ambiente que prefieren marcas que priorizan las prácticas ecológicas. Las aplicaciones medioambientales de las máquinas de vasos de papel no son sólo una tendencia sino una necesidad creciente en una industria que avanza hacia un futuro más sostenible. Beneficios de las máquinas de vasos de papel3.1 Impacto AmbientalUno de los beneficios más importantes de las máquinas de vasos de papel es su impacto positivo en el medio ambiente en comparación con las alternativas de plástico. Los vasos de papel, especialmente los fabricados con papel reciclado o de origen sostenible, se descomponen mucho más rápido que los vasos de plástico, lo que reduce la carga en los vertederos. El cambio hacia vasos de papel biodegradables y compostables mejora aún más este beneficio medioambiental. Al utilizar máquinas de vasos de papel, las empresas pueden contribuir a reducir los residuos plásticos, que es una gran preocupación a nivel mundial. Además, producir vasos de papel localmente utilizando estas máquinas puede reducir la huella de carbono asociada con el transporte de vasos desde los fabricantes hasta los usuarios finales. Las certificaciones de sostenibilidad, como las del Forest Stewardship Council (FSC), validan aún más las credenciales medioambientales de la producción de vasos de papel, lo que facilita que las empresas demuestren su compromiso con la sostenibilidad. 3.2 RentabilidadAdemás de los beneficios medioambientales, las máquinas de vasos de papel ofrecen importantes ventajas de costes. Si bien la inversión inicial en una máquina puede ser sustancial, los ahorros a largo plazo en los costos de producción son considerables. Producir vasos internamente elimina la necesidad de comprar vasos prefabricados, que pueden ser más costosos, especialmente si se tienen en cuenta los costos de envío. Las máquinas energéticamente eficientes contribuyen aún más al ahorro de costes al reducir el consumo de electricidad. La automatización proporcionada por las modernas máquinas de vasos de papel también genera ahorros de mano de obra, ya que se necesitan menos operadores para operar la máquina en comparación con los métodos de producción manual. Además, al producir vasos bajo demanda, las empresas pueden gestionar mejor su inventario, reduciendo el desperdicio y los costos asociados con el almacenamiento de grandes cantidades de vasos prefabricados. 3.3 Capacidades de personalizaciónOtro beneficio importante de las máquinas de vasos de papel es su capacidad para producir vasos personalizados.La marca es crucial en el competitivo mercado actual y los vasos de papel impresos personalizados ofrecen una oportunidad única para que las empresas refuercen su identidad de marca. Con la máquina adecuada, las empresas pueden producir vasos con sus logotipos, eslóganes e incluso diseños de temporada, lo que ayuda a crear una experiencia memorable para el cliente. La flexibilidad para cambiar entre diferentes tamaños y diseños de tazas también permite a las empresas atender una gama más amplia de preferencias de los clientes. Las tazas personalizadas también pueden mejorar la percepción del consumidor, ya que a menudo se asocian con mayor calidad y profesionalismo. Para las empresas que buscan diferenciarse en un mercado saturado, la capacidad de producir vasos de papel de marca internamente es un activo valioso. Últimas innovaciones en máquinas de vasos de papel4.1 Tecnologías de automatización avanzadasLas últimas máquinas de vasos de papel incorporan cada vez más tecnologías de automatización avanzadas para mejorar la eficiencia y reducir el desperdicio. Uno de los avances más significativos es la integración de la inteligencia artificial (IA), que permite a las máquinas optimizar los procesos de producción en tiempo real. La IA puede ayudar a reducir el desperdicio de material ajustando la configuración en función de la calidad de los materiales de entrada, garantizando una producción consistente sin intervención humana. Los sensores inteligentes son otra innovación que mejora la eficiencia de la máquina al monitorear varios parámetros, como la temperatura y la presión, y realizar los ajustes necesarios. Estos sensores también pueden detectar problemas potenciales antes de que provoquen averías, lo que reduce el tiempo de inactividad y los costes de mantenimiento. Los sistemas de monitoreo remoto son cada vez más comunes, lo que permite a los operadores realizar un seguimiento del rendimiento de la máquina y realizar ajustes desde cualquier lugar con una conexión a Internet. Esto no sólo mejora la eficiencia sino que también proporciona una mayor flexibilidad en la gestión de la producción. 4.2 Nuevas tecnologías de materialesLas innovaciones en tecnologías de materiales también están impulsando cambios en la industria de los vasos de papel. Uno de los avances más prometedores es el uso de recubrimientos de base biológica, como el PLA, que ofrecen una alternativa más sostenible a los recubrimientos tradicionales de PE. El PLA está elaborado a partir de recursos renovables y es totalmente compostable, lo que lo convierte en una opción atractiva para los consumidores conscientes del medio ambiente. Además, ha habido un interés creciente en el uso de papel reciclado para la producción de vasos, lo que reduce aún más el impacto ambiental. También se están desarrollando nuevas tecnologías de tinta e impresión para trabajar con estos materiales sostenibles. Por ejemplo, las tintas a base de agua, que son menos dañinas para el medio ambiente, se utilizan cada vez más. Estas innovaciones no sólo mejoran la sostenibilidad de los vasos de papel, sino que también abren nuevas oportunidades para que las empresas se diferencien ofreciendo productos ecológicos. 4.3 Modelos energéticamente eficientesA medida que los costos de la energía siguen aumentando, también ha aumentado la demanda de máquinas para fabricar vasos de papel energéticamente eficientes. Los fabricantes están respondiendo desarrollando modelos que consumen menos energía sin comprometer el rendimiento. Algunas de estas máquinas están diseñadas con motores de bajo consumo de energía y sistemas de calefacción energéticamente eficientes que reducen el uso general de energía durante la producción. Las máquinas de vasos de papel que funcionan con energía solar son otra innovación interesante que ofrece una forma de producir vasos con un impacto ambiental mínimo. Estas máquinas utilizan paneles solares para generar la electricidad necesaria para la producción, lo que las convierte en una opción ideal para las empresas que buscan reducir su huella de carbono. Además, algunas máquinas están equipadas con sistemas de recuperación de calor que capturan y reutilizan el calor generado durante la producción, mejorando aún más la eficiencia energética y reduciendo los costos operativos. Perspectivas futuras de las máquinas de vasos de papel5.1 Tendencias del mercado y proyecciones de crecimientoSe espera que la demanda mundial de vasos de papel siga creciendo, impulsada por una mayor conciencia ambiental y regulaciones gubernamentales destinadas a reducir los desechos plásticos. A medida que más consumidores opten por productos ecológicos, también se espera que se expanda el mercado de máquinas para fabricar vasos de papel. El crecimiento es particularmente fuerte en regiones con regulaciones ambientales estrictas, como Europa y América del Norte, donde las empresas están cada vez más obligadas a utilizar envases sostenibles. Los mercados emergentes de Asia y África también están experimentando un crecimiento significativo, impulsado por el aumento de los ingresos y la expansión de la industria de alimentos y bebidas. El comportamiento del consumidor es otro factor clave, ya que cada vez más personas están dispuestas a pagar más por productos sostenibles. Se espera que esta tendencia continúe, con proyecciones que indican un crecimiento constante en la demanda de vasos de papel y las máquinas que los producen. 5.2 Cambios regulatorios e impactosLas regulaciones gubernamentales juegan un papel crucial en la configuración de la industria de los vasos de papel. En muchas regiones, las regulaciones se están volviendo más estrictas, con prohibiciones de plásticos de un solo uso y exigencias de envases sostenibles. Estos cambios están impulsando la innovación en la industria de las máquinas para fabricar vasos de papel, a medida que los fabricantes desarrollan nuevas tecnologías y materiales para cumplir con los requisitos reglamentarios. Por ejemplo, la Directiva sobre plásticos de un solo uso de la Unión Europea ha provocado un aumento en la demanda de vasos de papel biodegradables y compostables. En respuesta, los fabricantes se están centrando en desarrollar máquinas que puedan producir vasos que cumplan con estos nuevos estándares. Los estándares de sostenibilidad, como los del FSC y el Programa para el respaldo de la certificación forestal (PEFC), también están influyendo en el diseño y el funcionamiento de las máquinas, a medida que las empresas buscan cumplir con estas certificaciones. A medida que las regulaciones sigan evolucionando, mantenerse a la vanguardia de estos cambios será crucial para las empresas de la industria de los vasos de papel. 5.3 Innovaciones en el horizonteDe cara al futuro, se vislumbran en el horizonte varias innovaciones interesantes para la industria de los vasos de papel. Uno de los más prometedores es el potencial de la impresión 3D en la producción de vasos de papel. Esta tecnología podría revolucionar la industria al permitir diseños altamente personalizados y reducir el desperdicio de material. La nanotecnología es otra área de interés, con potencial para crear recubrimientos más duraderos y resistentes al calor para vasos de papel. Esto podría conducir al desarrollo de tazas que sean aún más respetuosas con el medio ambiente y al mismo tiempo mantengan la funcionalidad necesaria para las bebidas calientes. También se espera que el avance hacia una economía circular impulse la innovación, con más énfasis en el reciclaje y la reutilización de materiales. Las futuras máquinas de vasos de papel podrían diseñarse teniendo en cuenta estos principios, permitiendo la producción de vasos que no sólo sean sostenibles sino que también estén totalmente integrados en un sistema de circuito cerrado. Análisis comparativo: máquinas de vasos de papel frente a alternativas6.1 Vasos de papel versus vasos de plásticoAl comparar vasos de papel con vasos de plástico, la diferencia más significativa radica en su impacto medioambiental. Los vasos de plástico son conocidos por su contribución a la contaminación plástica global, ya que tardan cientos de años en descomponerse. Por el contrario, los vasos de papel, especialmente los fabricados con papel reciclado o de origen sostenible, se descomponen mucho más rápido, lo que reduce su impacto en los vertederos. Sin embargo, es importante tener en cuenta que no todos los vasos de papel son iguales. Los que tienen revestimientos de plástico pueden ser más difíciles de reciclar, aunque siguen representando una mejor opción que los vasos totalmente de plástico. En términos de costo, los vasos de plástico suelen ser más baratos de producir, pero esta ventaja está disminuyendo a medida que las regulaciones ambientales y las preferencias de los consumidores cambian hacia opciones más sostenibles. Además, las percepciones de los consumidores juegan un papel importante en esta comparación, ya que muchas personas ahora consideran que los vasos de papel son la opción más responsable. 6.2 Vasos de papel versus vasos reutilizablesEl debate entre vasos de papel de un solo uso y vasos reutilizables está en curso, con argumentos válidos en ambos lados. Los vasos reutilizables, fabricados con materiales como el acero inoxidable o el vidrio, ofrecen la ventaja obvia de reducir el desperdicio. Sin embargo, también requieren energía y recursos para producirse, y es necesario lavarlos después de cada uso, lo que consume agua y electricidad. Para las empresas, la elección entre ofrecer vasos de papel o reutilizables suele depender del contexto específico. Por ejemplo, los vasos de papel pueden resultar más prácticos para eventos o establecimientos de comida rápida donde la comodidad y la higiene son las principales prioridades. Por otro lado, los vasos reutilizables podrían ser una mejor opción para restaurantes o cafeterías donde se anima a los clientes a reducir el desperdicio. También vale la pena considerar los costos del ciclo de vida de los vasos reutilizables, que pueden ser más altos que los de los vasos de papel si se tienen en cuenta los costos de limpieza y posibles roturas. 6.3 Vasos de papel frente a otras alternativas biodegradables Además de los vasos de papel, se están utilizando otros materiales biodegradables para producir vasos desechables, como el bambú, el almidón de maíz y la caña de azúcar. Estos materiales ofrecen la ventaja de ser totalmente biodegradables y, a menudo, compostables, lo que los convierte en una opción atractiva para los consumidores preocupados por el medio ambiente. Sin embargo, también presentan sus propios desafíos. Por ejemplo, los vasos de bambú pueden ser más caros de producir y es posible que no tengan tanta aceptación en el mercado como los vasos de papel. Se suelen utilizar tazas de almidón de maíz y caña de azúcar. en regiones con acceso a instalaciones de compostaje industrial, ya que requieren condiciones específicas para descomponerse de manera efectiva. En comparación con los vasos de papel, estas alternativas pueden ofrecer beneficios ambientales similares, pero pueden implicar costos de producción más altos o disponibilidad limitada. Para las empresas que buscan adoptar alternativas biodegradables, es importante considerar el ciclo de vida completo del producto y la infraestructura disponible para su eliminación. Guía del usuario para operar máquinas de vasos de papel7.1 Configuración e instalaciónInstalar una máquina de vasos de papel requiere una planificación y preparación cuidadosas. El primer paso es garantizar que el sitio de producción cumpla con todos los requisitos necesarios, incluido el espacio, el suministro de energía y la ventilación adecuados. La mayoría de las máquinas necesitarán un área dedicada con piso estable para soportar el peso del equipo. El proceso de instalación generalmente implica colocar la máquina, conectarla a la fuente de alimentación y calibrar la configuración de acuerdo con las instrucciones del fabricante. Es fundamental seguir atentamente los pasos de instalación para evitar problemas durante el funcionamiento. La calibración inicial es crucial para garantizar que la máquina produzca tazas del tamaño y la calidad correctos. Esto puede implicar ajustar la alimentación del papel, los elementos calefactores y los mecanismos de corte. Una vez que la máquina está configurada y calibrada, está lista para comenzar la producción, pero es importante monitorear de cerca las primeras ejecuciones de producción para garantizar que todo funcione correctamente. 7.2 Operación diaria y flujo de trabajoOperar una máquina de vasos de papel implica varias tareas diarias para garantizar una producción fluida. Normalmente, el día comienza encendiendo la máquina y comprobando que todos los sistemas funcionan correctamente. Esto incluye inspeccionar la alimentación del papel, verificar los niveles de tinta (si se trata de impresión) y asegurarse de que los elementos calefactores estén a la temperatura correcta. Durante la producción, es importante monitorear la máquina continuamente, atento a cualquier señal de mal funcionamiento o problemas de calidad. Esto podría implicar verificar la alineación del papel, la consistencia de las impresiones y la integridad estructural de los vasos. El control de calidad es un proceso continuo en el que los operadores inspeccionan periódicamente los productos terminados para garantizar que cumplan con los estándares requeridos. Si se detecta algún problema, es posible que sea necesario ajustar la configuración de la máquina o detenerla temporalmente para solucionar el problema. 7.3 Solución de problemas comunesIncluso con las mejores prácticas de mantenimiento, las máquinas de vasos de papel pueden encontrar problemas que interrumpan la producción. Uno de los problemas más comunes son los atascos en la máquina, que pueden ocurrir si la alimentación del papel está desalineada o si hay un bloqueo en el mecanismo de corte. Para eliminar un atasco, se debe detener la máquina y retirar la obstrucción con cuidado. Es importante abordar la causa raíz del atasco para evitar que vuelva a ocurrir. Los problemas de tinta y de impresión son otro problema común, especialmente si la máquina no está calibrada correctamente. La mala calidad de impresión, la desalineación o las manchas pueden afectar la apariencia del producto final. Estos problemas a menudo se pueden resolver ajustando la configuración de impresión o reemplazando los cartuchos de tinta. También pueden ocurrir errores de alimentación de papel, como atascos o doble alimentación, que pueden requerir ajustes en la tensión del papel o en los rodillos de alimentación. La resolución de problemas y el mantenimiento periódicos son clave para minimizar el tiempo de inactividad y garantizar una producción constante. 7.4 Mantenimiento y cuidado regularesEl mantenimiento regular es esencial para que las máquinas de vasos de papel funcionen de manera eficiente y prolonguen su vida útil. La limpieza diaria es una de las tareas de mantenimiento más importantes, ya que ayuda a prevenir la contaminación y la acumulación de materiales que pueden afectar el rendimiento de la máquina. Por lo general, esto implica limpiar la alimentación del papel, las cuchillas de corte y los elementos calefactores. La lubricación es otra tarea crítica, ya que garantiza que todas las piezas móviles funcionen sin problemas y reduce el desgaste. Dependiendo de la máquina, es posible que sea necesario reemplazar ciertas piezas periódicamente, como cuchillas de corte, sellos o elementos calefactores. Mantener un programa de mantenimiento ayuda a garantizar que estas tareas se realicen a tiempo y reduce el riesgo de averías inesperadas. Muchos fabricantes proporcionan guías de mantenimiento detalladas y seguir estas recomendaciones puede ayudar a prevenir problemas comunes y mantener la máquina en óptimas condiciones. ConclusiónLas máquinas de vasos de papel son una herramienta esencial para las empresas de los sectores de alimentos y bebidas, atención sanitaria y comercio minorista, y ofrecen una alternativa sostenible a los vasos de plástico. Al comprender las especificaciones técnicas, las aplicaciones, los beneficios, los desafíos y las tendencias futuras asociadas con estas máquinas, las empresas pueden tomar decisiones informadas que se alineen con sus necesidades de producción y objetivos ambientales. Ya sea que esté buscando iniciar un nuevo negocio o expandir una operación existente, elegir la máquina de vasos de papel adecuada es crucial para el éxito. Con la máquina adecuada, puede producir vasos de papel personalizados de alta calidad que satisfagan las demandas de sus clientes y minimicen el impacto medioambiental. A medida que la industria continúa evolucionando, mantenerse informado sobre las últimas innovaciones y tendencias lo ayudará a seguir siendo competitivo y lograr el éxito a largo plazo. Si tiene alguna solicitud sobre una máquina para fabricar vasos de papel, no dude en contactarnos. contáctanos para conseguir un apoyo.

LEE MAS

La guía definitiva para máquinas de vasos de papel: encuentre la máquina adecuada para sus necesidades

La guía definitiva para máquinas de vasos de papel: encuentre la máquina adecuada para sus necesidades

Dominar la calidad de los vasos de papel desechables: una guía definitiva

Dominar la calidad de los vasos de papel desechables: una guía definitiva

Principio de funcionamiento de la máquina para fabricar vasos de papel

Principio de funcionamiento de la máquina para fabricar vasos de papel

Ventajas de los vasos/platos de papel biodegradable

Ventajas de los vasos/platos de papel biodegradable