When purchasing a high-quality straw extrusion machine, the most crucial decision to make is whether to opt for a 50mm or 65mm main screw extruder.

This guide is designed to help you understand the technical differences and make a good choice whether you want to enter straw manufacturing or are already a straw making machine manufacturer.

This guide compares the 50 mm and 65 mm main screw extruders, focusing on:

Production capacity

Suitable straw diameter range

Cost-efficiency

Setup complexity

Practical considerations for straw manufacturers

This article will guide you in selecting the ideal plastic straw machine for your factory, whether you're manufacturing traditional PP straws, biodegradable PLA straws, or require adjustable output volume.

|

Feature |

50 mm Screw Extruder |

65 mm Screw Extruder |

|---|---|---|

|

💨 Output Capacity |

~20–35 kg/h |

~60–100+ kg/h |

|

⚡ Motor Power |

7.5–11 kW |

15–22 kW |

|

🔌 Energy Consumption |

Lower |

Higher |

|

📏 Machine Size |

Compact |

Larger footprint |

|

💵 Equipment Cost |

Lower |

Higher (machine + motor + cooling) |

|

⚙️ Residence Time |

Shorter (less thermal risk) |

Longer (may overprocess if output too low) |

|

🧰 Maintenance |

Easier to maintain |

More robust components, heavier parts |

|

🎛️ Control Requirements |

Simple |

More critical — needs precise controls for stability |

|

🛠️ Die Options |

Standard, up to dual-die setup |

Supports larger dies, multi-line outputs |

Both options are compatible with plastic straw-making machines as well as PLA straw-making machines. The right screw size ensures optimized performance of your drinking straw extrusion machine.

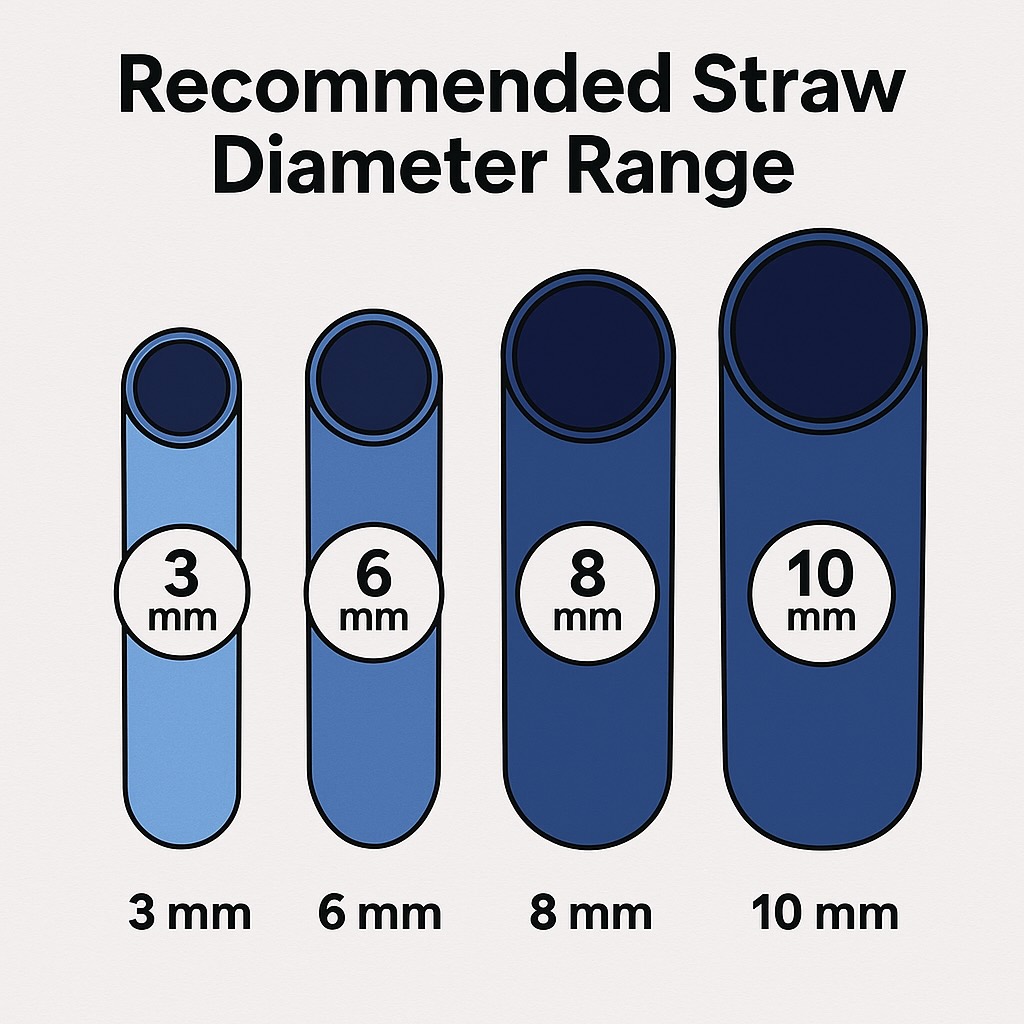

|

|

Straw Type |

Diameter (mm) |

Comment |

|---|---|---|

|

Regular drinking straw |

3–6 mm |

Ideal |

|

Medium straw |

6–8 mm |

Good |

|

Bubble tea straw |

8–10 mm |

Acceptable with lower speed |

|

Jumbo straw |

10–12 mm |

Not recommended unless low volume |

|

Straw Type |

Diameter (mm) |

Comment |

|---|---|---|

|

Medium straw |

6–8 mm |

Good |

|

Bubble tea straw |

8–10 mm |

Ideal |

|

Jumbo straw |

10–12 mm |

Ideal |

|

Small straw <5 mm |

3–4 mm |

Technically possible but needs precise control |

For regular drinking straw production (3–8 mm), a 50 mm screw is ideal. For manufacturers producing thick or jumbo straws, opt for a 65 mm screw.

Pros:

Lower energy and material use

Ideal for startups or small/medium batches

Easier maintenance and operation

Fast ROI

Cons:

Limited capacity for large-diameter straws

May bottleneck in high-volume scenarios

Pros:

Higher output capacity

Better for large-diameter or multi-line production

More scalable for mass production

Cons:

Higher energy costs

More complex setup and control

Slower material changeover

Higher initial investment

For those concerned about plastic straw making machine price, the 50 mm screw offers a more budget-friendly entry point, especially for first-time investors.

|

Use Case |

Recommended Screw |

|---|---|

|

Starting a new straw business |

✅ 50 mm |

|

Mostly small-diameter straws (3–6 mm) |

✅ 50 mm |

|

High-volume demand (24/7 operation) |

✅ 65 mm |

|

Producing jumbo straws (10–12 mm) |

✅ 65 mm |

|

Running multi-die head setup |

✅ 65 mm |

|

Limited factory space or power |

✅ 50 mm |

|

Frequent material or color changes |

✅ 50 mm |

Whether you’re producing with a PP straw making machine or exploring newer biodegradable straw machines, aligning your machine choice with your production plan is crucial.

|

Situation |

Go with… |

|---|---|

|

You want low investment, ease of use, and flexible batch production |

50 mm |

|

You need high output, large straws, or multiple lines |

65 mm |

For over 80% of plastic straw machine users targeting 3–8 mm diameter straws, the 50 mm screw offers the most balanced, efficient solution. As your production scales, the 65 mm becomes the preferred choice—especially for biodegradable straw making machine setups or multi-line output systems.

🔧 Looking to set up your own straw production line? We’re a trusted straw making machine manufacturer with full solutions, including:

Full consulting on equipment sizing and output optimization

📩 Contact us now to get a custom quote or consultation today!